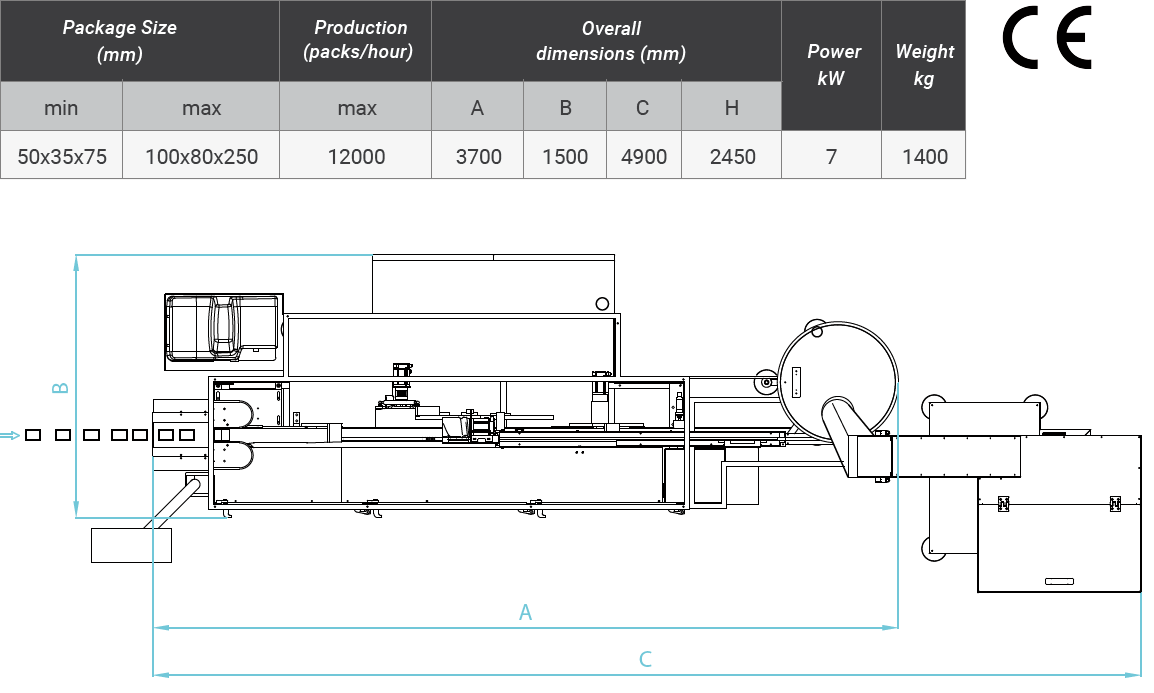

MT121

Cap applicator

AUTOMATIC MACHINE TO APPLY PLASTIC CAPS ON PACKAGES AND BOXES OF VARIOUS SIZES

The caps are poured into a hopper in bulk, orientated and picked up continuously by the machine via suction cups. A hot-melt adhesive system allows an even layer of glue to be applied on the cap that is immediately applied with precision and pressed down on the package until it is perfectly bonded.

Possibility of applying clip caps as well as screw caps of different shapes and sizes on liquid packages (brick or gable-top) as well as on boxes for solid products.

Characteristics of the standard machine

- The MT121 is a fast and reliable machine thanks to its high production capacity (over 12000 caps glued per hour, depending on the type of cap) and continuous operation

- Extremely easy to use and set: the touch screen allows you to view the operating condition of the machine and to adjust the bonding of the cap even while the machine is working

- Minimal maintenance

- Handled by interpolated brushless servomotors

- Possibility of remote assistance and monitoring

Optional

- Possibility of changing package size rapidly and adjusting the cap in all directions from the touch screen even while the machine is activated

- Possibility of centering the cap with extreme precision onto the desired position of the package by means of a vision system

- Possibility of orientating the cap by means of a vision system